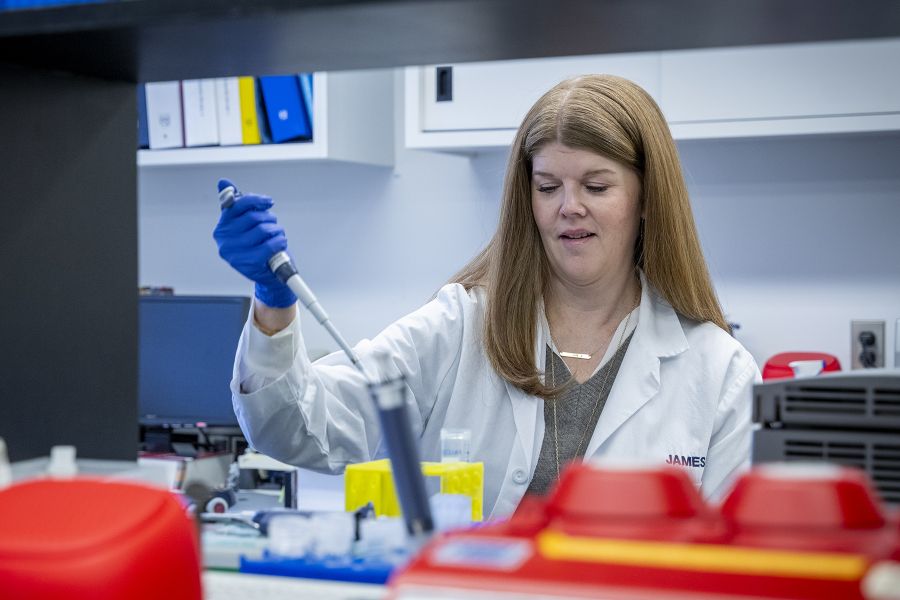

A team of clinicians and engineers at Kingston Health Sciences Centre and Queen’s University are exploring the potential of sleep apnea technology for mass-producing ventilators – fast.

Queen’s University’s Faculty of Engineering and Applied Science, the Human Mobility Research Centre and Ingenuity Labs have joined forces with Kingston Health Science’s Centre (KHSC) health professionals to take on the Code Life Ventilator Challenge, a global call to design a ventilator that can be created quickly and deployed anywhere around the world. View QVent video here.

The Code Life Ventilator Challenge is a 2-week sprint created by the Montreal General Hospital Foundation in collaboration with the Research Institute of the McGill University Health Centre. The challenge calls on teams to design a simple, low-cost, easy-to-manufacture, and easy-to maintain ventilator to help ease massive shortages during the coronavirus crisis.

The local team is working on a design that uses Continuous Positive Airway Pressure (CPAP) machines in its design. This technology, which helps healthy people with sleep apnea breathe more easily, has the potential to be modified to support or replace breathing for a coronavirus patient.

The team has been able to create prototypes thanks to donations of at least 50 CPAP machines from individuals who responded to a social media request for help.

“We came up with a design that’s completely modular, using readily available parts,” says Tim Bryant,” says Tim Bryant, team member and Professor Emeritus, Queen’s Mechanical Engineering. “Modules can be reconfigured or replaced depending on the user’s need.”

“There’s a global shortage of ventilators, and with the outbreak still rapidly progressing, this has become a life-and-death issue,” he says. “Now is the time to come together to respond to this crisis with real solutions. This challenge will save lives.”

“This is collaborative, interdisciplinary problem-solving at its best, ” says Steve Smith, Vice-Dean Research, Faculty of Heath Sciences, Queen’s, Vice President, Health Research, KHSC and President & CEO, KGH Research Institute. “I congratulate the faculty, students and staff at both of our institutions for their ingenuity, drive and humanitarian spirit in addressing a critical global need.”

The team of 14 includes Prof. Rick Sellens, a specialist in fluid mechanics in Queen’s Mechanical Engineering, Dr. Ramiro Arellano, anesthesiologist at KHSC and Head of Anesthesiology, Queen’s, and KHSC’s Ventilator Equipment Pool, a unique, province-wide service that provides equipment and expertise for in-home ventilation across Ontario.

“We’ve had a groundswell of support from all quarters,” Bryant says. “Dr. Arellano has been pivotal in working with this interdisciplinary team, and the ventilator group gave us a lot of input – they’ve been absolutely amazing. This has been a collaboration that crosses all the borders – I can’t imagine a more cross-disciplinary problem.”

A panel of experts will be judging all designs and posting the top three online for free downloading to anyone who is able to manufacture them.

Gallery

Queen’s/KHSC YGK Ventilator Challenge team used components from sleep apnea CPAP machines to create an easy-to-use ventilator.